Aluminium Composite Panels are sandwiched panels made up of layers of aluminium sheets sandwiched over a polyethylene core. It is made of combustible or non-combustible thermoplastic material that is utilised on the outside and inside of structures. Two aluminium sheets are well attached to a non-aluminum core to create these composite panels. Aluminium composite panels may be used in any sort of structure. The panels’ primary function is to support the dead wall while also adding aesthetic value to the building’s elevation. They are available in a variety of colours, sizes, and forms.

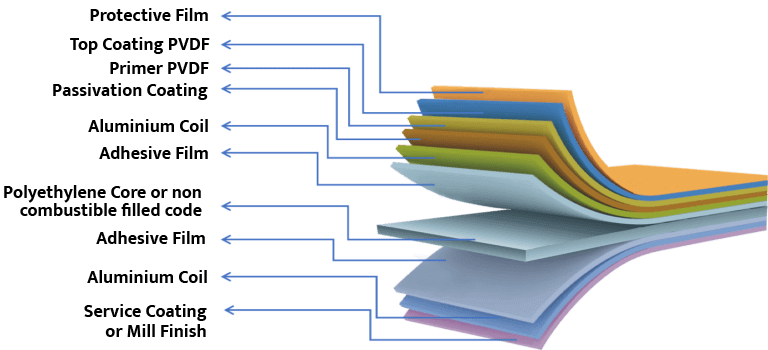

Composition Of Aluminium Composite Panels.

Aluminium composite panels are made using the lamination method. Its top and bottom layers are coated aluminium sheets, with a polyethylene core sandwiched between them. It is formed of;

- Protection Film

- PVDF/Polyester Resin Based Coating

- Primer Coating

- Aluminium Coil

- Adhesive Film (Polyolefin)

- Polyethylene Core (LDPE)

- Adhesive Film (Polyolefin)

- Aluminium Coil

- Service Coating (Anti-corrosive)

The Benefits of Aluminum Composite Panels.

Aluminium is a lighter material than other cladding panel materials. When exposed to air, it develops a unique coating of aluminium oxide that prevents rusting and corrosion. Aluminium composite panels are anodized, which enhances the thickness of the aluminium panels. Aluminium materials are unaffected by rain and sunshine, which is a significant advantage of employing them. Its benefits include:

- Can bend, fold and turn easily

- Flatness

- Wide range of colours and finishes

- Excellent thermal and acoustic insulation

- Borer, termite, and fungi resistant

- Available in different thicknesses

- Can be made fire retardant

- Have antimicrobial properties

- UV ray resistant

- Lightweight and corrosion and shock resistant

- Environment-friendly

- Fully recyclable

- Withstands extreme weather conditions

Types of Aluminium Composite Panels.

Fire Retardant ACP

A Fire Retardant ACP sheet has a honeycomb pattern that reduces the intensity of the fire and the heat produced by any fire outbreak. The air bubbles in the honeycomb pattern guarantee that the fire is trapped by generating a vacuum between the layers.

Non-Combustible ACP

It is the same as a traditional composite panel; however, what makes it different is the technology of the core, which is constructed from a 100% aluminium structure rather than any combustible material. It is made of an advanced mineral compound that is best for restraining the flammability of the minor polymeric content and restricting flame propagation and smoke generation.

Anti-Bacterial ACP

Anti-bacterial ACP sheets actively protect you and your loved ones from potentially hazardous germs such as coliform, staphylococcus aureus, salmonella, enteritis bacteria, and so on.

Aluminum Composite Panel Applications.

- Exterior elements include the façade, canopy, overhang, soffit, and more.

- Interior – wall coverings, fake ceilings, cupboards, closets, modular kitchens, table tops, column covers, and other accessories.

- Corporate Identity Design – Signage, kiosks, totems, point-of-purchase displays, fascia, and so on.

- For all forms of facade cladding.

- To cover columns & Cladding for a balcony.

- Canopies, tunnels, subway interiors, phone booths, column coverings, and restorations are all examples of public works projects.