The effort to build a greener, safer environment is more essential than ever. This implies that recycling and coming up with innovative uses for waste materials are issues that many organizations are tackling. When it comes to leftover cement, steel and other building materials. Construction firms can be one of the major waste generators.

HOW TO RECYCLE THE CONCRETE?

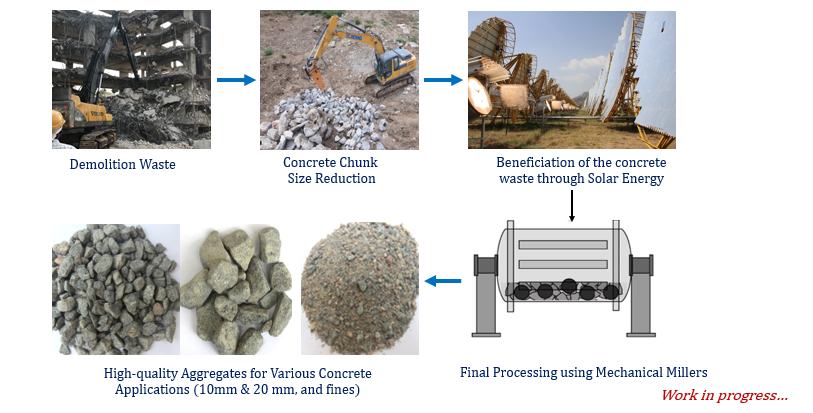

The common procedure for recycling of concrete is as follows,

Step 1-Large chunks of concrete are first crushed using specialized industrial machinery that uses ballistic trajectories and crushers.

Step 2-It involves examining the concrete to get rid of any impurities or debris after it has been broken down. Other procedures and tools, such as water flotation, separators, and magnets, are used to clean concrete of additional contaminants.

Step 3– Concrete is sorted into large and small particles. Pulverization is a substitute technique for recycling concrete. This, however, makes the separation process more complex and might lead to increased contamination from smaller products.

Benefits of Recycling Concrete.

Concrete recycling at building sites has a significant advantage:

o Concrete recycling predominately aids in reducing overall building waste.

o Prolonging the feasibility of landfills

o Lowering the expenditures associated with disposal and tipping rates.

o Minimizing transportation expenses because concrete can be recycled as near as possible to construction sites.

What Applications Does Recycled Concrete Have?

Similar to how gravel and stones are utilized, recycled concrete can also be used. These are a few instances:

o New asphalt pavement’s foundation-Rubbleization is the technique of dismantling old concrete pavement and using it as a foundation for new asphalt.

o Outdoor surfaces- To minimize the amount of runoff that needs to be treated by storm sewer systems, permeable concrete is utilized in driveways, parking lots, and pathways. Groundwater levels are also replenished by permeable concrete. Crushed concrete can be used to make porous surfaces that function similarly to permeable concrete in some outdoor spaces.

o Mulch for landscaping- Rather than gravel, recycled concrete that has been carefully crushed and sorted might be utilized.

o Utility trenches- typically coated in gravel to help with drainage, however, recycled concrete can be used in their place as the bed foundation material.

o Concrete aggregate- Recycled concrete may be substituted for fresh aggregates in a concrete mix.